The production unit is characterized by a very high competence in all aspects of thermal cutting, very high quality standards and an innate attention to the customer. All this means: processing of every type of metal profile. The machines allow operators to be able to carry out complex machining operations, guaranteeing such high quality standards that they no longer have to operate on the product after the first processing. The pride of this production unit is the UNI EN ISO 9001: 2000 certification on all the four types of processing carried out, to guarantee the highest quality standards on the product before, during and after processing. All the technical staff has continuous training, in order to be able to offer the customer new technologies, taking full advantage of the potential offered by the machines present in the company.

Cutting specialists

The production unit is developed by exploiting three types of cutting, allowing us to produce pieces of different sizes, consistencies and materials, always guaranteeing excellent workmanship, with a finished cut of superior quality.

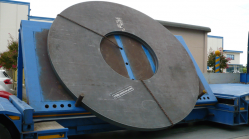

The four CENTERS OSSITAGLIO, operating on a 60-meter bench, allow for quality cuts and rapid execution, thus cutting down storage times and guaranteeing prompt delivery.

Thanks to C.N.C. we can produce:

- single pieces

- long series

- small or "super-large" oxy-cut up to 800 mm thick and 30 ton of weight

- oxy-cut on one or more surfaces

- trimming and forming of forged products

- K V Y chamfers for welding preparation

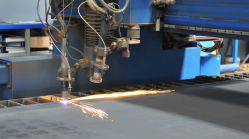

The plasma cutting centers

Equipped with high-definition generators, also controlled by the CNC, they operate on a 36-meter working range and are able to perform high-quality and performance cuts on: carbon steel, alloy steel, stainless steel, aluminum, copper and its alloys from 0.5 to 30 mm in thickness, while maintaining their mechanical and structural characteristics unaltered, thus offering a multitude of products that always respond to the customer's wishes. It is also possible to carry out marking with zinc dust or engraving to facilitate any subsequent processing (drilling, bending, etc.).

The laser cutting plant

Equipped with automatic pallet changer, it operates on a work area of 6 meters x 2 meters, so as to minimize machine downtime. The power of the 5000 Watt system allows the following materials to be processed with extreme quality and precision:

- construction steel up to 25 mm;

- stainless steel up to 20 mm;

- aluminum and its alloys up to 12 mm.

If required, the particular products are straightened and bending can be carried out up to a maximum of 3300 tons per 12 meters. The products can be supplied deburred, polished and satin-finished or tumbled.

The machines are served by a series of dedicated lifting means that make loading and unloading fast:

- nr. 1 crane bridge ton. 15 + 15

- nr. 1 crane bridge ton. 40

- nr. crane bridge ton. 10

- nr. 2 crane bridge ton. 6,3

- nr. 3 cranes dedicated to the cutting line

Seguici su Facebook